Walking Furnace

Walking Furnace

- The specifications of a Walking Furnace are:

- Heat output: A Walking Furnace have a heat output rating measured in British Thermal Units (BTUs) that indicates the amount of heat it can produce per hour.

- Heating capacity: The Walking Furnace’s heating capacity is the maximum area or volume of a home it can effectively heat.

- Efficiency rating: Its efficiency rating is a measure of its ability to convert energy input into useful heat output. This rating is typically expressed as an Annual Fuel Utilization Efficiency (AFUE) or Seasonal Energy Efficiency Ratio (SEER) rating.

- Control system: The Walking Furnace come with a thermostat or other control system that allows the user to set and adjust the temperature and other settings.

- Size and dimensions: It come in different sizes and configurations to accommodate different home sizes and heating needs.

- Installation requirements: The Walking Furnace have specific installation requirements, such as the type of fuel source it uses, the need for water supply and drainage, and ventilation requirements.

Description

Walking furnace is a revolutionary new home heating system that offers homeowners a more efficient and cost-effective way to heat their home. By using a combination of hot water, insulation, and air circulation, walking furnace is able to maintain a consistent temperature throughout the home, while using significantly less energy than traditional heating systems.

Walking Furnace operates by circulating hot water and air throughout the home, using insulation to maintain a consistent temperature. This approach to heating can be more efficient and cost-effective than traditional heating systems, which often rely on centralized heating units or furnaces to heat the entire home.

Walking Furnace: working principle

The Walking Furnace works by continuously circulating hot water through the pipes in the home, which heats the surrounding air and helps to maintain a consistent temperature throughout the house. The insulation in the walls and ceiling of the home helps to retain this heat and prevent energy loss. The Walking Furnace also uses air circulation to distribute the heat evenly throughout the home, ensuring that every room is heated evenly. By using this combination of hot water, insulation, and air circulation, the Walking Furnace is able to operate more efficiently and use less energy than traditional heating systems, resulting in cost savings for homeowners.

The characteristics

- Hot water circulation: The Walking Furnace use a system of pipes and pumps to circulate hot water throughout the home, providing consistent heating to all rooms.

- Insulation: It rely on insulation materials in the walls, floors, and ceilings of the home to help retain heat and reduce energy loss.

- Air circulation: In addition to hot water, the Walking Furnace use air circulation to help distribute heat evenly throughout the home.

- Energy efficiency: By using a combination of hot water circulation, insulation, and air circulation, the Walking Furnace may be designed to use less energy than traditional heating systems, which can help reduce utility costs for homeowners.

- Control options: The Walking Furnace may offer various control options, such as programmable thermostats or smartphone apps, that allow homeowners to adjust the temperature and settings remotely.

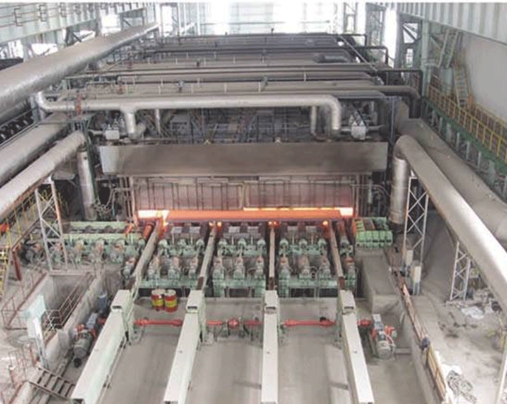

Walking Beam Type Slab Heater Technical Data Main Technical Parameters

| Name | Technical parameters |

| Description | Walking beam type copper/brass slab heater |

| Material | Copper ,brass,cupro-nickel alloy etc |

| Slab size | Thickness 160mm160mm Width 400~420mm400~420mm Length 3000~4600mm3000~4600mm Standard Max. weight: 2.75t/piece/(160×420×4600mm) 2.75t/(160×420×4600mm) |

| Heating capacity | Minium 12t/h, 4slab/h(1slab:160×420×4600mm) :12t/h 4/h(160×420×4600mm) |

| Heating temperature | 730~750ºC±5ºC(max 850ºC) |

| Hearth temperature () |

800~900ºC |

| Fuel | Natural gas LNG |

| Heat value | 8900Kcal/ Nm3 |

| Air preheating temperature | 250~450ºC |

| Heat efficiency of the furnace | ≥45% |

| Thermal control pattern | Auto/ manual,impulse , remote control ,, |

| Burner type | Imported flat flame burners of Germany KROM schroder. heating zone each burner:23 Nm3/h;soaking zone each burner:15 Nm3/h KROM schroder.23 Nm3/h;15Nm3/h |

| Number of burners | Total: 18 PCS,heating zone:8PCS, Soaking zone: 10 PCS 18,8,10 |

| Rated burning capacity | Max:334 Nm3/h :334 Nm3/h |

| Dimension of the hearth | W5000×H1200×L8000mm 5000×1200×8000mm |

| Loading capacity | 16slabs/batch×2.75t/piece=44t/batch 16/×2.75t/=44t/ |

| Total length of furnace | ~11m ~11 |

| Loading and unloading method | End feeding and side discharge |

| Loading pattern | Single row,3 zones,preheating zone2.5m,heating zone 3.5m,soaking zone 2m ,, 2.5m,3.5m,2.0m |

| Vertical movement of walking beams: |

Lifting: 90mm, 90mm Lowering: 80mm 80mm |

| Horizontal travel of walking beams: | 500mm |

| Heat interchanger | Hot tubular exchanger |

| Heated up time | ~4 hours ~4 |

| Quantity of heated up zone | 3 zones 4sections 34 |

| Material and space | Slab: W420mm; slab in furnace:16pcs; Gap between slab and slab: 80mm; Stroke : 500mm 420mm;16;80mm;500mm |