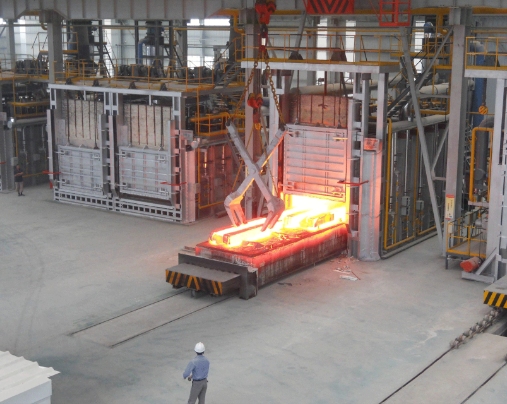

Regenerative Forging Furnace

Regenerative Forging Furnace

- The product specifications for a regenerative forging furnace may vary depending on the specific requirements of the forging process, but some common specifications include:

- Heating capacity: This refers to the amount of metal that the furnace can heat in a given time. The heating capacity is typically measured in tons per hour (TPH).

- Temperature range: The furnace should be able to reach and maintain a specific temperature range suitable for the type of metal being forged. The temperature range can vary depending on the metal grade and the forging process type.

- Fuel type: Regenerative forging furnaces can be powered by a variety of fuels, including natural gas, coke oven gas, and oil. The choice of fuel will depend on factors such as availability, cost, and environmental regulations.

- Efficiency: A high-efficiency furnace can save energy and reduce operating costs. The efficiency of a regenerative forging furnace can be measured in terms of fuel consumption per ton of metal processed.

- Regenerative system: The regenerative system is a key component of the furnace, allowing it to recycle waste heat and improve energy efficiency. The regenerative system typically consists of a pair of heat exchangers that store and release heat from the furnace exhaust gases.

- Control system: The furnace should have a reliable control system that allows operators to adjust the temperature and other parameters as needed. The control system should also provide safety features such as alarms and automatic shut-offs in case of emergencies

Description

A Regenerative Forging Furnace is a type of furnace used in the metal forging process. It is designed to efficiently heat metals to high temperatures to make them more malleable and easier to shape. The Regenerative Forging Furnace works by using a regenerative system to preheat the combustion air before it enters the furnace. This system consists of two chambers filled with a heat-absorbing material, such as ceramic brick, which alternates between being heated by the combustion gases and being used to preheat the incoming air. This results in more efficient use of fuel and a reduction in energy costs. The Regenerative Forging Furnace is often used in the production of large forgings, such as those used in the automotive and aerospace industries. It is capable of reaching temperatures of up to 2,400 degrees Fahrenheit, making it ideal for heating high-strength metals such as titanium, stainless steel, and nickel alloys.

Structure: Regenerative Forging Furnace

The Regenerative Forging Furnace typically consists of the following components:

- Combustion chamber: This is the main part of the furnace where the fuel, typically natural gas or propane, is burned to produce heat.

- Regenerator chambers: The furnace has two regenerator chambers filled with heat-absorbing material, such as ceramic brick. These chambers alternate between being heated by the combustion gases and being used to preheat the incoming air, resulting in more efficient use of fuel.

- Air ducts: The preheated air is then directed to the combustion chamber through air ducts.

- Exhaust system: The furnace also has an exhaust system that removes the waste gases produced during the combustion process.

- Heating elements: Heating elements are used to supplement the heat produced by the combustion process and maintain the desired temperature inside the furnace.

Scope of application: Regenerative Forging Furnace

The Regenerative Forging Furnace is widely used in the metal forging industry for heating and shaping various types of metals, including:

- High-strength metals: The furnace is capable of reaching temperatures of up to 2,400 degrees Fahrenheit, making it suitable for heating high-strength metals such as titanium, stainless steel, and nickel alloys.

- Non-ferrous metals: The furnace can also be used for heating non-ferrous metals such as aluminum, copper, and brass.

- Large forgings: The Regenerative Forging Furnace is particularly useful for the production of large forgings such as those used in the automotive and aerospace industries.

- Precision forging: The furnace is also suitable for precision forging applications where tight tolerances and high-quality surface finishes are required.

Function:

The function of the Regenerative Forging Furnace is to efficiently heat metals to high temperatures to make them more malleable and easier to shape. This is achieved through the following process:

- Fuel combustion: The furnace burns fuel, typically natural gas or propane, in a combustion chamber to produce heat.

- Preheating of air: The heat produced by the combustion process is used to preheat the incoming air in one of the regenerator chambers.

- Heating of metal: The preheated air is then directed to the combustion chamber, where it combines with the fuel to produce a high-temperature flame that heats the metal to the desired temperature.

- Regeneration: The waste gases produced during the combustion process are directed to the other regenerator chamber, where they transfer their heat to the heat-absorbing material. This material is then used to preheat the incoming air in the next cycle, resulting in more efficient use of fuel.

- Temperature control: The furnace is equipped with a control system that monitors and regulates the temperature, airflow, and fuel consumption to ensure optimal performance and maintain a consistent temperature throughout the heating process.

Technical indicators:

- Maximum temperature: Yinuo’s Regenerative Forging Furnaces are capable of reaching a maximum temperature of 2400 degrees Fahrenheit (1316 degrees Celsius), which is suitable for heating high-strength metals such as titanium, stainless steel, and nickel alloys.

- Heating rate: The heating rate of Regenerative Forging Furnaces is typically between 150-200 degrees Fahrenheit (83-111 degrees Celsius) per minute, which allows for efficient heating of the metal parts.

- Fuel consumption: These are designed to consume a minimum amount of fuel per unit of metal heated, resulting in lower operating costs.

- Heating uniformity: They are equipped with heating elements and temperature control systems that ensure a consistent temperature throughout the heating chamber, resulting in uniform heating of the metal parts.

- Control accuracy: Forging Furnaces are equipped with advanced control systems that provide accurate and reliable control of the heating process, including temperature, airflow, and fuel consumption.