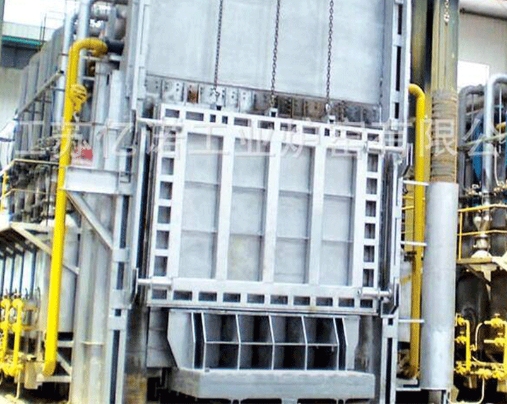

Regenerative Forging Furnace/Regenerative Forging Heating Furnace

Regenerative Forging Furnace/Regenerative Forging Heating Furnace

- Here are some specifications of Regenerative Forging Furnace

- Fuel source: The furnace can be fueled by natural gas, propane, or other combustible fuels.

- Temperature range: The Regenerative Forging Furnace can typically achieve temperatures between 800°C (1472°F) and 1300°C (2372°F) or higher, depending on the specific application.

- Heating capacity: The furnace can be designed to heat various sizes of metal billets, ingots, or other raw materials. The heating capacity may range from a few hundred kilograms to several tonnes.

- Conveyor system: The furnace may include a conveyor system that can move the raw material through the furnace for even heating.

- Regenerative burners: The furnace features two or more regenerative burners positioned at opposite ends of the furnace.

Description

| OEM | Yes | Brand | YINUO, Others |

| Product name | Metal heating equipment | Application | heat treatment |

| Working Temperature | 1300℃/2372℉ | Carrying capacity | Customers define (kg) |

| Overall dimensions | Customer Needs (mm) | Type | Heating furnace |

A Regenerative Forging Furnace is a type of furnace used in the metal forging industry to heat metal billets, ingots, or other raw materials prior to forging. This type of furnace is known for its high efficiency and is widely used in the production of forged metal products.

The Regenerative Forging Furnace operates by using regenerative burners that alternate between heating and storing heat. The burners are positioned at opposite ends of the furnace and are connected to a network of refractory-lined chambers known as the regenerators. These chambers are filled with ceramic material, which absorbs and stores heat generated by the burners.

During operation, the burners are used to heat the raw material being forged, and the hot exhaust gases are directed through the regenerators, where they transfer their heat to the ceramic material. The burners are then shut off, and the hot ceramic material is used to preheat the incoming combustion air for the next cycle, allowing for high energy efficiency and reduced fuel consumption.

The Regenerative Forging Furnace also typically features a conveyor system that moves the raw material through the furnace, ensuring even heating and reducing the risk of hot spots or cold spots.

Overall, the Regenerative Forging Furnace is a highly efficient and effective solution for heating metal raw materials in the forging process. Its use of regenerative burners and ceramic regenerators allows for efficient heat storage and transfer, resulting in reduced fuel consumption and lower operating costs.

Working principle: Regenerative Forging Furnace

The working principle of a Regenerative Forging Furnace involves the use of regenerative burners that alternate between heating and storing heat, and a conveyor system that moves the raw material through the furnace for even heating. Here are the main steps involved in the working principle of a Regenerative Forging Furnace:

- Burners: The Regenerative Forging Furnace features two or more burners positioned at opposite ends of the furnace. These burners are typically fueled by natural gas or other combustible fuels.

- Preheating: The burners are used to heat the raw material being forged, and the hot exhaust gases are directed through a network of refractory-lined chambers known as the regenerators. These chambers are filled with ceramic material, which absorbs and stores the heat generated by the burners.

- Heat storage: Once the regenerators are filled with hot ceramic material, the burners are shut off. The hot ceramic material is then used to preheat the incoming combustion air for the next cycle. This allows for efficient heat storage and transfer, reducing the amount of fuel needed for subsequent heating cycles.

- Conveyor system: The Regenerative Forging Furnace also features a conveyor system that moves the raw material through the furnace. The conveyor system is designed to provide even heating of the raw material, reducing the risk of hot spots or cold spots.

- Regeneration: Once the hot ceramic material has been used to preheat the incoming combustion air, the direction of the airflow is reversed. The hot exhaust gases are then directed through the other regenerator, allowing it to absorb and store heat while the first regenerator is used to preheat the incoming combustion air. This alternating cycle allows for efficient heat regeneration and transfer.

The characteristics

The Regenerative Forging Furnace is known for several key characteristics, including:

- High efficiency: The Regenerative Forging Furnace is highly efficient due to its use of regenerative burners and ceramic regenerators, which allow for efficient heat storage and transfer. This results in reduced fuel consumption and lower operating costs.

- Even heating: The furnace features a conveyor system that moves the raw material through the furnace for even heating, reducing the risk of hot spots or cold spots.

- Precise temperature control: The Regenerative Forging Furnace is equipped with advanced temperature control systems that allow for precise control over the heating process, ensuring high-quality finished products.

- Versatility: The furnace can be used to heat a wide range of metal raw materials, including billets, ingots, and other shapes.

- Reduced emissions: The use of regenerative burners and ceramic regenerators in the furnace results in reduced emissions compared to traditional furnace designs.